Industrial Support Systems

Comprehensive machinery diagnostics, repair, and maintenance.

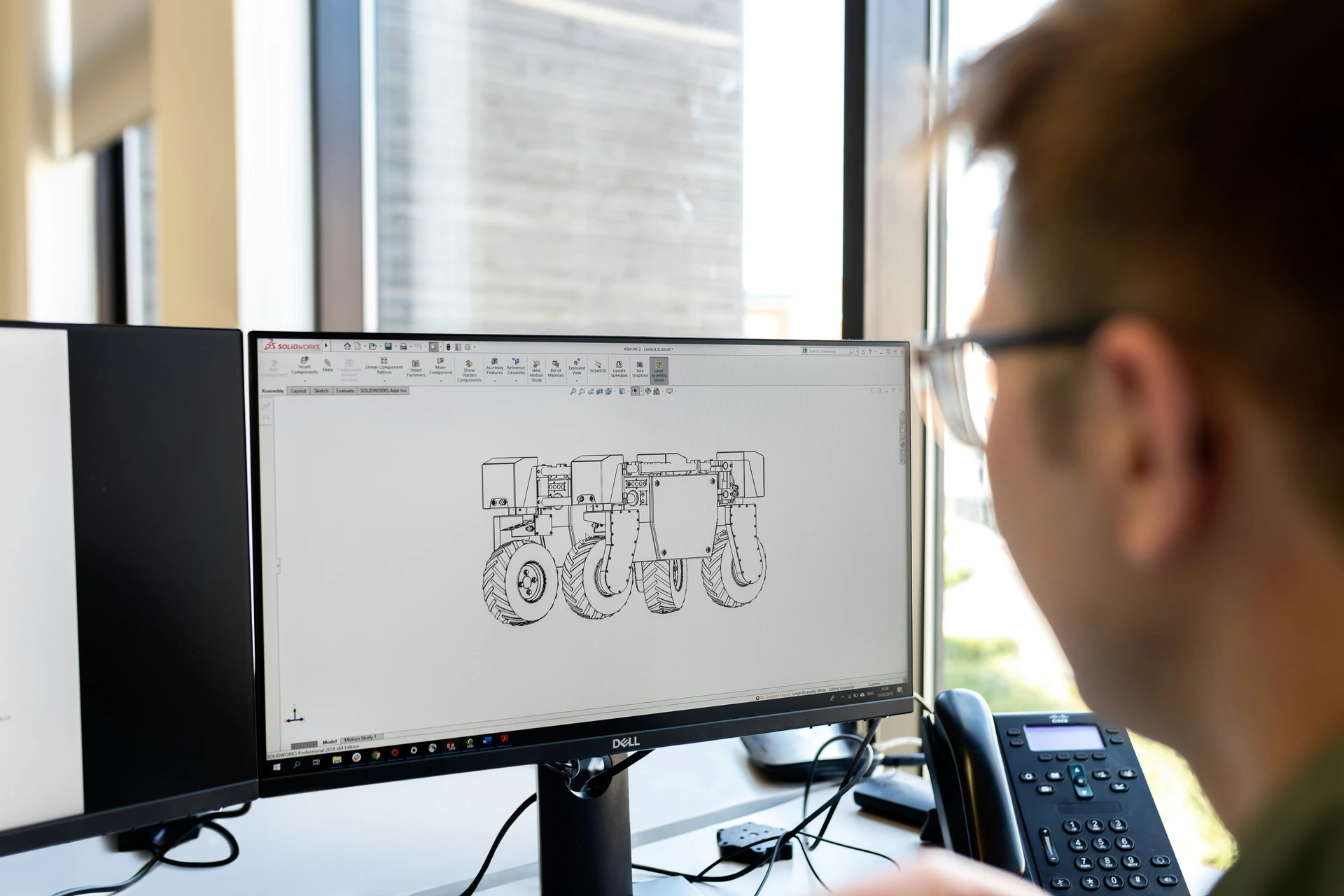

Advanced System Analysis

Comprehensive diagnostic testing identifies performance issues, wear patterns, and system inefficiencies using advanced instrumentation and analysis techniques.

Load Testing

Performance measurement under operating conditions to identify capacity limitations and efficiency deviations.

Vibration Analysis

Pattern recognition in rotational equipment to detect bearing wear, misalignment, and imbalance conditions.

Electrical System Tracing

Circuit analysis, insulation testing, and power quality measurement to identify electrical faults and inefficiencies.

Thermal Diagnostics

Temperature profiling and thermal imaging to detect overheating, cooling system failures, and thermal stress points.

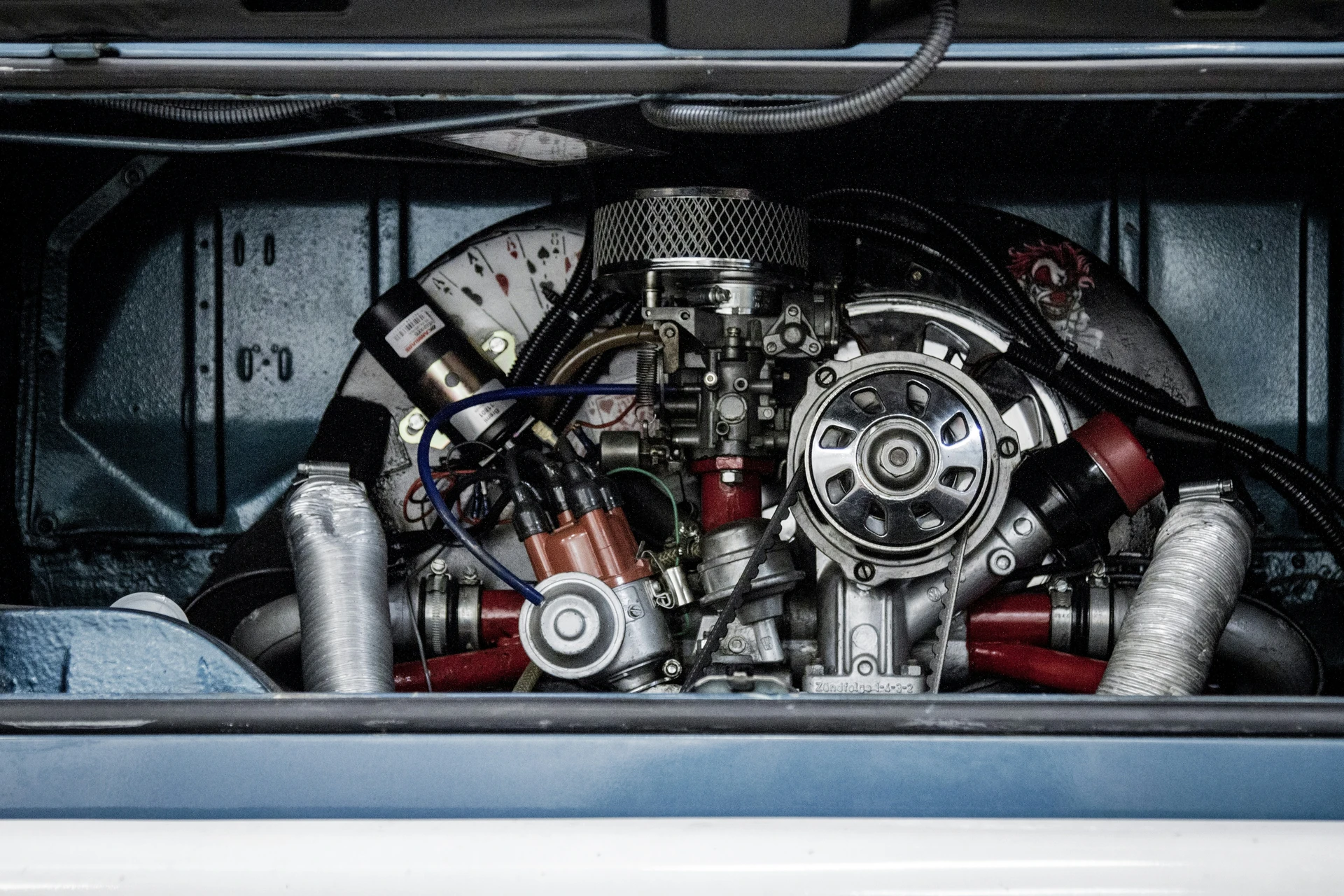

Precision Machinery Repair

Systematic repair procedures restore equipment to operational specifications using precision techniques and quality-controlled processes.

Mechanical Assemblies

Bearing replacement, shaft repair, seal installation, and component alignment to restore mechanical integrity.

Drive Systems

Motor repair, gearbox overhaul, coupling replacement, and drive train optimization for reliable power transmission.

Electrical Repairs

Winding replacement, control system repair, sensor calibration, and electrical component replacement.

Rotational Equipment

Pump repair, compressor overhaul, fan balancing, and rotating assembly restoration.

Preventive Maintenance Programs

Scheduled maintenance procedures extend equipment lifespan and prevent unexpected failures through systematic monitoring and early intervention.

Preventive Schedules

Time-based and condition-based maintenance scheduling to optimize equipment availability and minimize downtime.

Wear Pattern Tracking

Systematic monitoring of component wear to predict failure points and schedule replacements before breakdowns occur.

Efficiency Optimization

Performance tuning, lubrication optimization, and system adjustments to maintain peak operating efficiency.

Documentation

Maintenance records, performance trends, and component history for informed decision-making and lifecycle management.

Performance Optimization

System improvements and upgrades enhance efficiency, reduce energy consumption, and extend equipment operational lifespan.

System Balancing

Precision balancing of rotating equipment to reduce vibration, minimize wear, and improve operational smoothness.

Component Upgrades

Modern component integration to improve reliability, efficiency, and performance while maintaining system compatibility.

Efficiency Modeling

Performance analysis and optimization strategies to reduce operating costs and improve output quality.

Energy Reduction

Power consumption analysis and efficiency improvements to reduce energy costs and environmental impact.

Request Industrial Support

Contact us for diagnostics, repair, maintenance, or performance enhancement services.

Get Started