Engineering Method

Systematic approach to machinery performance and reliability.

Six-Stage Engineering Process

Every machinery diagnostic, repair, and maintenance task follows a systematic six-stage process designed to ensure precision, quality, and long-term reliability.

Assess

Initial system evaluation establishes performance baseline and identifies operational parameters.

Equipment specification review and operational history analysis

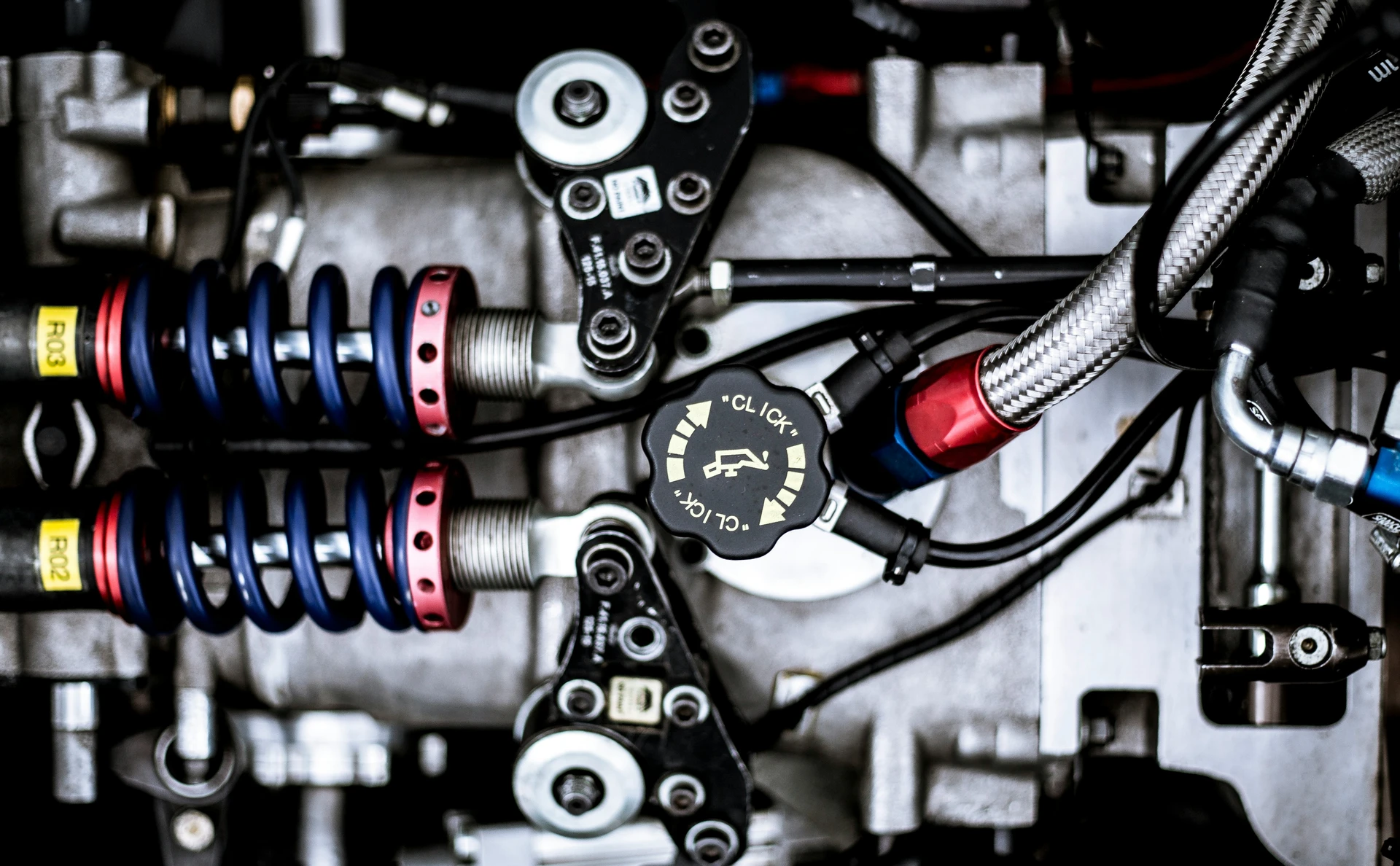

Visual inspection for obvious damage or wear patterns

Performance measurement under current operating conditions

Safety system verification and compliance check

Diagnose

Detailed analysis using advanced diagnostic tools identifies root causes and failure mechanisms.

Load testing to measure performance under specified conditions

Vibration analysis for bearing and alignment issues

Electrical diagnostics including insulation and power quality tests

Thermal imaging to detect temperature anomalies

Plan

Engineering solution design and resource allocation for efficient repair execution.

Repair procedure development based on diagnostic findings

Component specification and procurement planning

Tool and equipment preparation for precision work

Timeline estimation and downtime minimization strategy

Repair

Precision execution with quality control ensures repairs meet original specifications.

Systematic disassembly with component documentation

Precision repair techniques and component replacement

Assembly with proper torque specifications and alignment

Quality checkpoints throughout repair process

Test

Performance verification and load testing confirm system operation within specifications.

No-load testing to verify basic functionality

Progressive load testing to rated capacity

Performance measurement and comparison to baseline

Safety system verification and final inspection

Maintain

Ongoing monitoring and preventive care extends equipment lifespan and prevents future failures.

Maintenance schedule development based on operating conditions

Performance trend monitoring and wear pattern tracking

Preventive component replacement before failure occurs

Documentation and lifecycle management

Verified Results

Systematic

Structured process ensures consistent quality and reliable results.

Verified

Performance testing confirms repairs meet specifications.

Efficient

Optimized procedures minimize downtime and maximize availability.

Experience Systematic Engineering

Contact us to discuss your machinery diagnostics, repair, or maintenance requirements.

Get Started